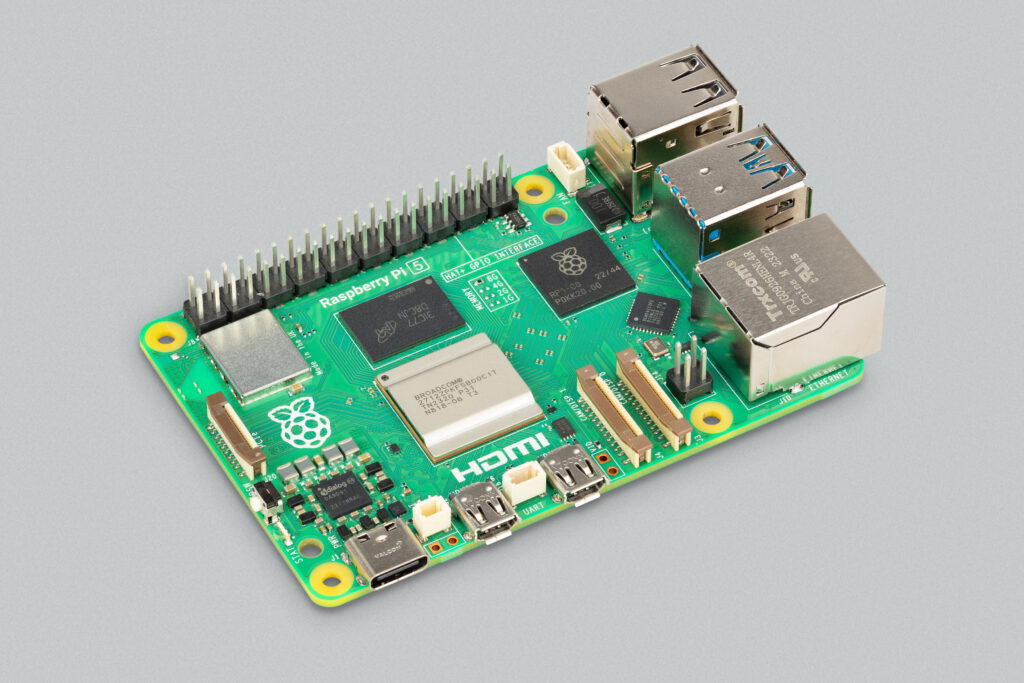

Today, we’re delighted to announce the launch of Raspberry Pi 5, coming at the end of October. Priced at $60 for the 4GB variant, and $80 for its 8GB sibling (plus your local taxes), virtually every aspect of the platform has been upgraded, delivering a no-compromises user experience. Raspberry Pi 5 comes with new features, it’s over twice as fast as its predecessor, and it’s the first Raspberry Pi computer to feature silicon designed in‑house here in Cambridge, UK.

Key features include:

2.4GHz quad-core 64-bit Arm Cortex-A76 CPU

VideoCore VII GPU, supporting OpenGL ES 3.1, Vulkan 1.2

Dual 4Kp60 HDMI® display output

4Kp60 HEVC decoder

Dual-band 802.11ac Wi-Fi®

Bluetooth 5.0 / Bluetooth Low Energy (BLE)

High-speed microSD card interface with SDR104 mode support

2 × USB 3.0 ports, supporting simultaneous 5Gbps operation

2 × USB 2.0 ports

Gigabit Ethernet, with PoE+ support (requires separate PoE+ HAT, coming soon)

2 × 4-lane MIPI camera/display transceivers

PCIe 2.0 x1 interface for fast peripherals

Raspberry Pi standard 40-pin GPIO header

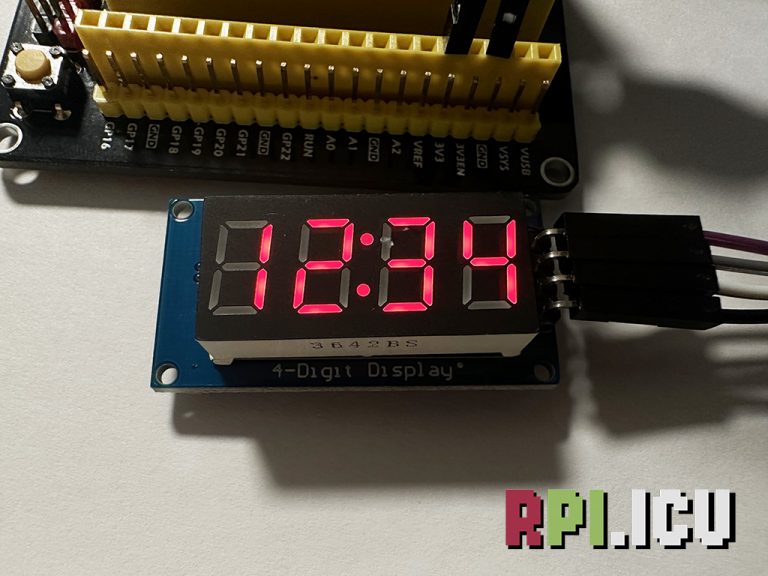

Real-time clock

Power button

In a break from recent tradition, we are announcing Raspberry Pi 5 before the product arrives on shelves. Units are available to pre-order today from many of our Approved Reseller partners, and we expect the first units to ship by the end of October.

Watch Eben do some talking about Raspberry Pi 5

We’re incredibly grateful to the community of makers and hackers who make Raspberry Pi what it is; you’ve been extraordinarily patient throughout the supply chain issues that have made our work so challenging over the last couple of years. We’d like to thank you: we’re going to ringfence all of the Raspberry Pi 5s we sell until at least the end of the year for single-unit sales to individuals, so you get the first bite of the cherry.

We’re also giving every print subscriber to The MagPi and HackSpace magazines a single-use code, giving them priority access to Raspberry Pi 5 hardware. Click those links to learn more about our Priority Boarding programme — and if you subscribe today, you can get your hands on a Priority Boarding pass too.

Cover of The MagPi magazine issue 143 (October 2023), with “Introducing… Raspberry Pi 5” cover feature

Cover of HackSpace magazine issue 71 (October 2023), with “Eben Upton presents Raspberry Pi 5” cover feature

Between now and the end of October, we’ll be running a series of regular articles and videos, focusing on different aspects of the platform. Keep checking in here.

A little history

Way back in June 2019, we launched Raspberry Pi 4, the first true PC-class Raspberry Pi computer. With a quad-core Arm Cortex-A72 processor clocked at 1.5GHz, it was roughly forty times faster than the original Raspberry Pi model from 2012. In many ways the timing was perfect: in March the following year, schools closed, and millions of schoolchildren around the world were sent to study from home. Tens of thousands of them were able to rely on a Raspberry Pi 4 as their primary PC.

Watch Raspberry Pi 5 show you all of its bits without talking

In the four years since then, Raspberry Pi 4, and its derivatives Raspberry Pi 400 and Compute Module 4, have become firm favourites of enthusiasts, educators, and professional design engineers worldwide. Modern Raspberry Pi 4 computers run 20% faster than the launch variant, with a core clock speed of 1.8GHz. And, despite the well publicised challenges that have affected the electronics supply chain over the last two years, we’ve made and sold over 14 million units of Raspberry Pi 4 in that time.

But time doesn’t stand still, and neither does our community’s appetite for performance. And since 2016 — the era of Raspberry Pi 3 — we’ve been quietly working on a much more radical overhaul of the Raspberry Pi platform. Today, that effort bears fruit, with the launch of Raspberry Pi 5: compared to Raspberry Pi 4, we have between two and three times the CPU and GPU performance; roughly twice the memory and I/O bandwidth; and for the first time we have Raspberry Pi silicon on a flagship Raspberry Pi device.

New platform, new chipset

Three new chips, each designed specifically for the Raspberry Pi 5 program, come together to deliver a step change in performance.

BCM2712

Close-up photo of part of the Raspberry Pi 5 board, centring the metal shield over the BCM2712 chip, with laser etching identifying the chip.

BCM2712 is a new 16-nanometer application processor (AP) from Broadcom, derived from the 28-nanometer BCM2711 AP which powers Raspberry Pi 4, with numerous architectural enhancements. At its heart is a quad-core 64-bit Arm Cortex-A76 processor, clocked at 2.4GHz, with 512KB per-core L2 caches, and a 2MB shared L3 cache. Cortex-A76 is three microarchitectural generations beyond Cortex-A72, and offers both more instructions per clock (IPC) and lower energy per instruction. The combination of a newer core, a higher clock speed, and a smaller process geometry yields a much faster Raspberry Pi, and one that consumes much less power for a given workload.

Our newer, faster CPU is complemented by a newer, faster GPU: Broadcom’s VideoCore VII, developed here in Cambridge, with fully open source Mesa drivers from our friends at Igalia. An updated VideoCore hardware video scaler (HVS) is capable of driving two simultaneous 4Kp60 HDMI displays, up from single 4Kp60 or dual 4Kp30 on Raspberry Pi 4. A 4Kp60 HEVC decoder and a new Image Sensor Pipeline (ISP), both developed at Raspberry Pi, round out the multimedia subsystem. To keep the system supplied with memory bandwidth, we have a 32-bit LPDDR4X SDRAM subsystem, running at 4267MT/s, up from an effective 2000MT/s on Raspberry Pi 4.

RP1

Previous Raspberry Pi generations were built on a monolithic AP architecture: while some peripheral functions were provided by an external device (the Via Labs VL805 USB controller and hub on Raspberry Pi 4, and the Microchip LAN951x and LAN7515 USB hub and Ethernet controller chips on earlier products), substantially all of the I/O functions were integrated into the AP itself. Fairly early in the history of Raspberry Pi, we realised that as we migrated the AP to progressively newer process nodes, this approach would eventually become both technically and economically unsustainable.

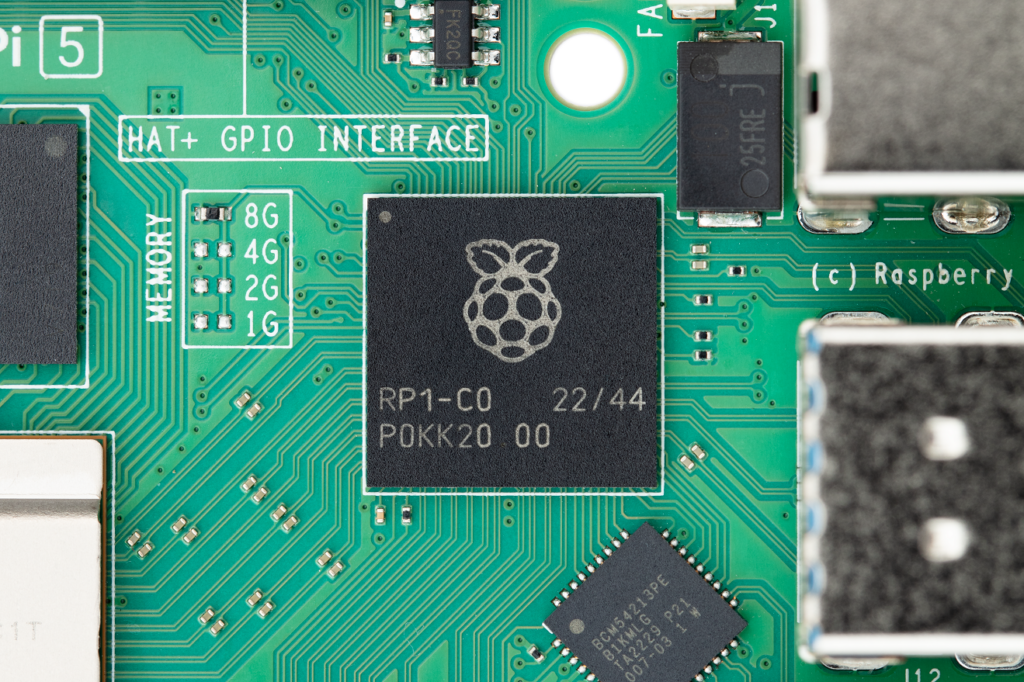

Close-up photo of part of the Raspberry Pi 5 board, centring the RP1 chip, on which the Raspberry Pi logo and text identifying the chip are printed

Raspberry Pi 5, in contrast, is built on a disaggregated chiplet architecture. Here, only the major fast digital functions, the SD card interface (for board layout reasons), and the very fastest interfaces (SDRAM, HDMI, and PCI Express) are provided by the AP. All other I/O functions are offloaded to a separate I/O controller, implemented on an older, cheaper process node, and connected to the AP via PCI Express.

RP1 is our I/O controller for Raspberry Pi 5, designed by the same team at Raspberry Pi that delivered the RP2040 microcontroller, and implemented, like RP2040, on TSMC’s mature 40LP process. It provides two USB 3.0 and two USB 2.0 interfaces; a Gigabit Ethernet controller; two four-lane MIPI transceivers for camera and display; analogue video output; 3.3V general-purpose I/O (GPIO); and the usual collection of GPIO-multiplexed low-speed interfaces (UART, SPI, I2C, I2S, and PWM). A four-lane PCI Express 2.0 interface provides a 16Gb/s link back to BCM2712.

Under development since 2016, RP1 is by a good margin the longest-running, most complex, and (at $15 million) most expensive program we’ve ever undertaken here at Raspberry Pi. It has undergone substantial evolution over the years, as our projected requirements have changed: the C0 step used on Raspberry Pi 5 is the third major revision of the silicon. And while its interfaces differ in fine detail from those of BCM2711, they have been designed to be very similar from a functional perspective, ensuring a high degree of compatibility with earlier Raspberry Pi devices.

DA9091

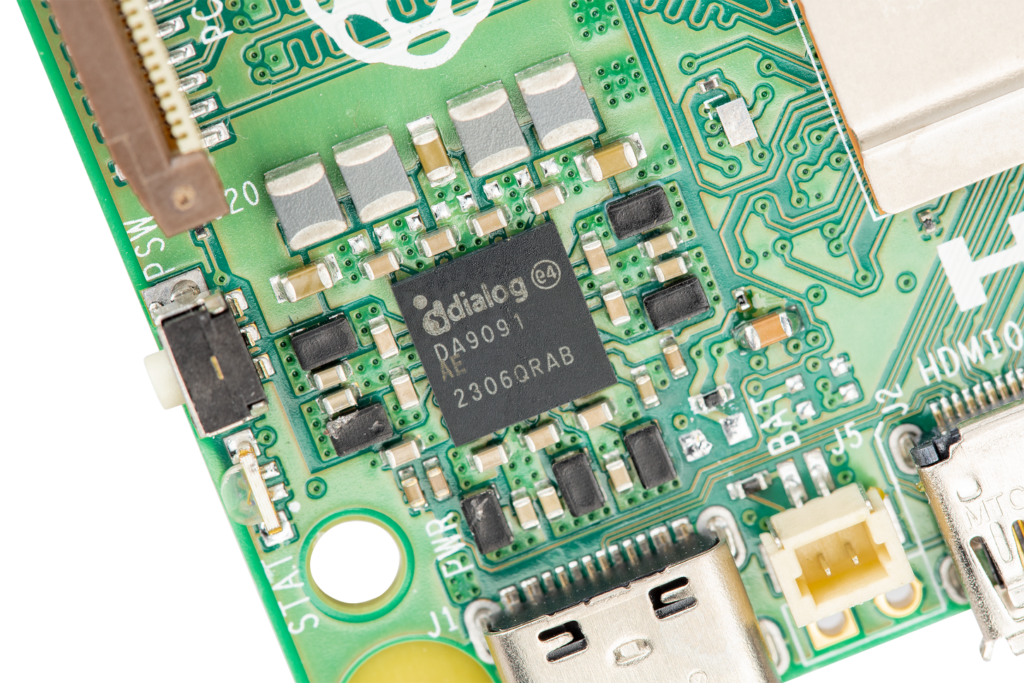

BCM2712 and RP1 are supported by the third new component of the chipset, the Renesas DA9091 “Gilmour” power-management IC (PMIC). This integrates eight separate switch-mode power supplies to generate the various voltages required by the board, including a quad-phase core supply, capable of providing 20 amps of current to power the Cortex-A76 cores and other digital logic in BCM2712.

Close-up photo of part of the Raspberry Pi 5 board, centring the DA9091 power-management IC, on which its name is printed

Like BCM2712, DA9091 is the product of a multi-year co-development effort. Working closely with the Renesas team in Edinburgh allowed us to produce a PMIC which is precisely tuned for our needs. And we were able to squeeze in two frequently requested features: a real-time clock (RTC), which can be powered by an external supercapacitor or a rechargeable lithium-manganese cell; and a PC-style power button, supporting hard and soft power-off and power-on events.

Two other elements of the chipset have been retained from Raspberry Pi 4. The Infineon CYW43455 combo chip provides dual-band 802.11ac Wi-Fi and Bluetooth 5.0 with Bluetooth Low-Energy (BLE); while the chip itself is unchanged, it is provided with a dedicated switched power supply rail for lower power consumption, and is connected to BCM2712 by an upgraded SDIO interface which supports DDR50 mode for higher potential throughput. As before, Ethernet connectivity is provided by a Broadcom BCM54213 Gigabit Ethernet PHY; this now sits at a jaunty 45-degree angle, a first for Raspberry Pi, and a source of enduring disappointment for orthogonal-layout enthusiast and CTO (Software) Gordon Hollingworth.

Form-factor evolution

On the outside, Raspberry Pi 5 closely resembles its predecessors. But, while retaining the overall credit-card-sized footprint, we’ve taken the opportunity to update some elements of the design, to align with the capabilities of the new chipset.

We’ve removed the four-pole composite video and analogue audio jack from the board. Composite video, now generated by RP1, is still available from a pair of 0.1”-spaced pads on the bottom edge of the board.

We now sport a pair of FPC connectors, in the space formerly occupied by the four-pole jack and camera connector. These are four-lane MIPI interfaces, using the same higher-density pinout found on various generations of Compute Module I/O board; and they are bi-directional (transceiver) interfaces, meaning that each one can connect either to a CSI-2 camera or to a DSI display. The space on the left of the board formerly occupied by the display connector now contains a smaller FPC connector which provides a single lane of PCI Express 2.0 connectivity for high-speed peripherals.

Close-up photo of part of the Raspberry Pi 5 board, centring the two FPC connectors, labelled CAM/DISP 0 and CAM/DISP 1

The Gigabit Ethernet jack has returned to its classic position in the bottom right corner of the board, after a brief sojourn in the top right on Raspberry Pi 4. And it’s brought with it the four-pin PoE connector, simplifying the board layout at the cost of a compatibility break with our existing PoE and PoE+ HATs.

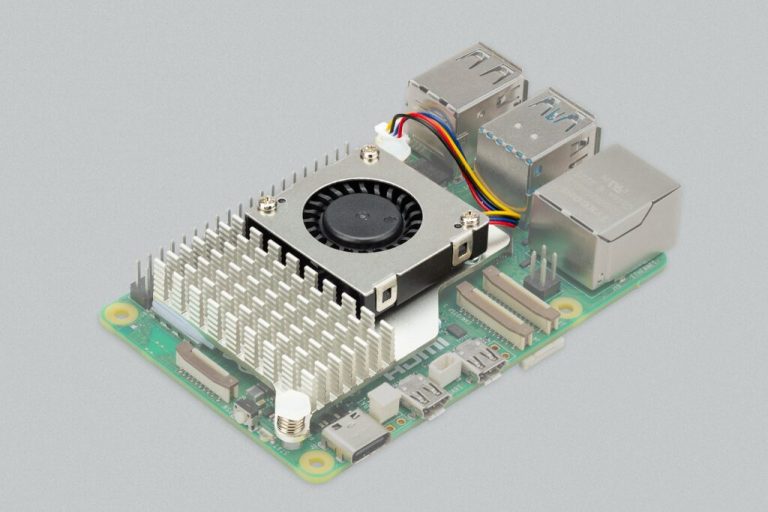

Finally, we’ve grown a pair of mounting holes for a heatsink, as well as JST connectors for the RTC battery (two pins), Arm debug and UART (three pins), and fan with PWM control and tacho feedback (four pins).

Designed in Cambridge, manufactured in Wales

Like all flagship Raspberry Pi products, Raspberry Pi 5 is built at the Sony UK Technology Centre in Pencoed, South Wales. We have been working with Sony since the launch of the first Raspberry Pi computer in 2012, and we’re firm believers in the benefits of manufacturing our products within a few hours’ drive of our engineering design centre in Cambridge: a decade of frequent interaction with the Sony team has helped us understand how to design products that can be built reliably, cheaply, and at massive scale.

Close-up photo of a corner of the Raspberry Pi 5 box, centred on a Welsh flag icon (red dragon rampant on a grey field against a white sky) beside the words “Made in the UK”.

Raspberry Pi 5 marks the introduction of a number of manufacturing innovations. One of these is intrusive reflow for connectors, which improves the mechanical quality of the product, increases throughput, and eliminates the costly and energy-intensive selective- or wave-solder process from the production flow. Others include fully routed panel singulation for cleaner board edges, and a new approach to production test inspired by our experiences testing our RP2040 microcontroller at scale.